Structural Safety Assessment of a Sunken Ship Considering Hull Corrosion and Damaged Members : Focus on the Sunken Ship ‘No. 7 HaeSung’

Abstract

Sunken ships cause damage to the environment due to the dispersal of fuel oil and harmful cargo goods in the hull. Since the sunken ship is mostly flooded by the seabed, it tends to be in a relatively stable condition. However, the heavy body, together with the load of remaining goods in the cargo hold, the constant contact with the seabed, and ocean currents and tidal waves, can affect dispersal of residual fuel oils out of the sunken ship. Corrosion of the sunken ship starts upon sinking, decreasing the thickness of the hull structure and sub-materials. Therefore, it is necessary to assess the structural stability against the potential breakdown of the sunken ship. Whilst evaluating the danger of the sunken ship, this result should be reflected in ‘the possible discharge’. This study was undertaken to suggest a procedure for a step by step evaluation to assess the structural stability a sunken ship. The structural stability assessment to estimate the collapsibility of the hull was structure targeted at the sunken ship ‘No. 7 HaeSung’, which was classified as the prime example for the intensive management of sunken ships. This study was undertaken to suggest a procedure for a step by step evaluation to assess the structural stability a sunken ship and to propose a method to conduct a structural safety assessment that estimates the collapsibility of the hull by targeting the sunken ship ‘No. 7 HaeSung’,which was classified as the prime example for the intensive management of sunken ships. The collapsibility of the hull structure was estimated Based on the damage size of the hull structure, and the corrosion rate of the hull structure and sub-materials due to the seawater after sinking. It was confirmed that there was a low possibility of the total destruction of the hull structure at the current time. However, there is a high possibility in the potential failure of the hull structure due to increased rate of corrosion thereafter. Therefore, we believe continuous study on influence of corrosion and marine environment change to sunken ship’s structural safety is necessary.

초록

침몰선박은 선체 내에 적재되어 있는 잔존연료 및 유해 화물 등의 유출로 인하여 주변 환경과 선박의 안전 항해에 피해 요인으로 작용할 수 있다. 대부분의 침몰선박은 해저에 침수된 상태로 비교적 안정적인 상태로 놓여있지만 선체 자중, 화물창의 잔존화물에 의한 하중과 해저면과의 접촉상태, 조류 및 해류 등의 영향으로 침몰선박 잔존연료 유출에 영향을 줄 수 있다. 침몰선박은 침몰 이후 부식이 진행되어 선체 구조부재의 두께가 지속적으로 감소하고 있는 상황이다. 따라서 침몰선박의 붕괴 가능성에 대한 구조안전성 평가가 필요하며 그 결과는 침몰선박의 위해도 평가요소 중 ‘유출가능성’ 평가 항목에 반영되어야 한다. 본 연구에서는 침몰선박의 구조 안전성 평가 방법에 대한 단계별 절차를 제시하고, 집중관리대상 침몰선박으로 분류된 ‘제7해성호’를 대상으로 선체구조의 붕괴 가능성을 추정하기 위한 구조 안전성 평가 방안을 제시한다. 침몰 당시 선체 손상 상태와 침몰 이후 선체구조 부재의 부식량 추정을 바탕으로 대상 침몰선박의 선체구조 붕괴 가능성을 산정한 결과, 현 상태에서는 전체적인 선체구조 붕괴가 일어날 가능성이 낮은 편으로 추정되지만, 향후 시간에 따른 부식량 증가로 인한 선체구조 붕괴가 일어날 가능성은 다소 높은 것으로 판단된다. 따라서 부식 및 해양환경 변화가 침몰선체 구조 안전성에 미치는 영향 등의 연구는 지속적으로 수행 되어져야 할 것으로 사료된다.

Keywords:

Sunken ship, Corrosion, Section modulus, Ultimate strength, Damage size키워드:

침몰선, 부식, 단면계수, 최종강도, 손상크기1. Introduction

A sunken ship is defined as a vessel of which the hull structure has lost its buoyancy due to cracking, fracture, cutting, and so on, resulting from various types of marine accidents including fires, grounding, collision, explosion, and floods. In such cases, the ship is unable to sail any more since she has sunk below sea level and has settled on the seabed. Due to the marine accident, potential ocean pollutants such as the fuel oil, cargo goods, and chemical substance, remain in the hull for a long time. These potential pollutants generate marine pollution, and can also interfere in the navigation and operation of other ships. This is especially true when the wreck is located near the main route or fishing grounds, and can cause another marine accident (Lee et al.[2015]).

As of December 2015, it is reported that 2,158 sunken ships are present along the coastline (Ministry of Oceans and Fisheries [2015]). Per the paragraph 2 of article 47 in the enforcement regulation under the paragraph 2 of article 83 of Marine Environment Administration Law, government conducted risk assessment on the sunken ships evaluating 7 points : the vessel class, the vessel scale, the residual fuel oil, the keel clearance, the sensitivity to the sea area environment, the possible discharge of harmful materials, and the marine transportation environment, and classified 64 ships as “object of general control”, 12 ships as “object of intensive control”, total of 76 vessels as the objects of target control. (Korea Marine Environment Management Corporation [2014]). Among the risk assessment aspects of sunken ships, ‘potential discharge’ of cargo goods and the residual fuel oil from sunken vessels is evaluated by theoretical weighted value only based on the age of the vessel. However, the potential collapse of the hull structure due to the corrosion rate and damage situation should also be considered as well as the age of the vessel.

Since the sunken ship is mostly flooded by the seabed, it tends to be in a relatively stable state since the hydrostatic pressure does not operate on both interior and exterior of the hull, and the load from tidal waves is ineffective on the hull. However, the heavy body, along with the load of remaining goods in the cargo hold, the constant contact with the seabed, and the load against ocean currents and tidal waves, has an effect on the ship where corrosion is a continuous process, thus decreasing the thickness of the hull structure and its sub-materials.

This study was therefore undertaken to assess the structural stability of the sunken vessels, by considering both the age of the sunken vessel and the corrosion rate and damage size. For the structural stability assessment of the sunken ship, it required the basic data, including main structural size of the ship, relevant information regarding the accident, etc. However, it is difficult to acquire drawings of the sunken ship as the major blueprints have been destroyed, and classified information has been withdrawn after decades of sinking under the sea. Taking this into consideration, this study proposes a procedure to evaluate the structural stability of the sunken ship, and a method to perform the stability assessment against the potential failure of the hull structure. According to the suggested procedure and method, we assessed ‘No. 7 HaeSung’, using it as the model example of intensive management, without drawings of the ship structure.

There is hardly any previous research on the sunken ship without drawings of the ship structure; hence, this study anticipates that this assessment method of the structural stability of the sunken ship can be further applied to interpret and analyze the potential failure of the sunken ships due to the corrosion, earthquake, and tidal waves.

2. Method for Assessing the Structural Stability of the Sunken Ship

2.1 A Method implemented to assess the structural stability

In general, the assessment of the structural stability of a vessel has to define the mid-ship section from the vessel design information based on the core resources, the vessel class, and the form; furthermore, it has to calculate the transverse section modulus of the vessel requested in Register. The transverse section modulus of the vessel is calculated with the mid-ship section, and the rule scantling of the facet is consistently extended over 40~60%. This is because the maximum value of the longitudinal bending moment of a ship occurs in the mid-ship, and this is the most critical point of the hull structure strength. Therefore, the structural stability assessment is performed after designing the cross-section structure of the vessel. The drawings of structure are required for understanding the structure of the ship, in order to determine the structural stability assessment. However, it is very difficult to acquire the drawings of the structure of a sunken ship, since the designs are discarded after a specified period.

This research therefore estimates the transverse section coefficient of the sunken vessel according to the written report of the vessel at the time of the accident, figures out the kind of vessel, the core resources, and the form, by studying the website information of other related vessels. The damage information of the vessel and the sinking status of the hull structure is studied through the video information acquired from the on-site investigation. The ship lying on the seabed is dissimilar to the general vessel normally operating on the hydrostatic pressure and the weight of tidal waves. It is estimated that the ship is operated by the heavy body, along with the loaded cargo goods, and the constant state in contact with the seabed, the hull slope, the weight of waves, and the combined loads of the weight.

This research estimates the calculation about the weight of waves and the exact calculation of the structural stability only in a general range. The exact assessment for the structural stability of the sunken ship is given by calculating the ultimate strength holding the hull structure itself, which is different from normally operating vessels.

2.2 Executional process of assessment of structural stability

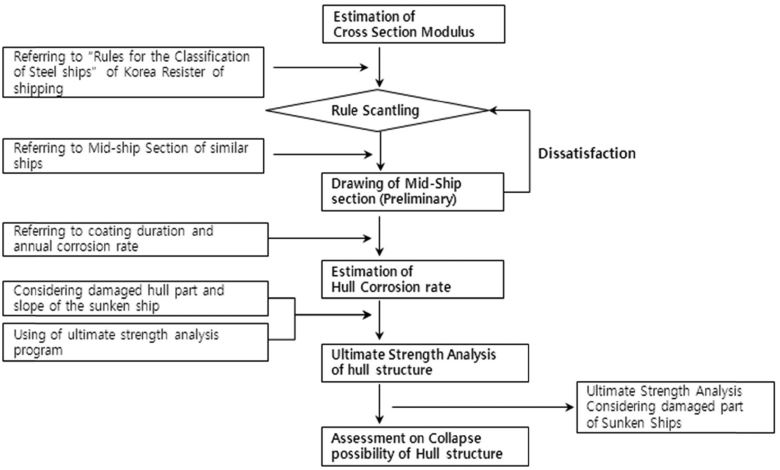

Figure 1 shows method used to evaluate and execute the procedure for the structural stability of the sunken ship. On the left of the figure is the data required for the step by step assessment of the structural stability. In order to evaluate the structural stability of the sunken ship: ① estimate the transverse section modulus of the vessel with reference to the central cross section of a similar ship ② calculate the rule scantling and draw the central cross section of the vessel. This has to be repeatedly executed so that it revises the rule scantling, the member value, etc., until the section modulus of the central cross section satisfies the section coefficient value in need ③ estimate the corrosive rate of the hull structure by taking the lifetime of coating, the annual corrosive rate, ages of the ship, and the period of sinking, into account ④ analyze the ultimate strength by using the ultimate strength program, considering the rate of the structural stability for the vessel at the time of the design ⑤ finally, evaluate the probability whether the hull structure failed after performing the analysis of the ultimate strength, considering the damaged submaterials of the sunken vessel.

According to this procedure, chapter 3 deals with the vessel design data needed for the structural stability assessment and the condition of the sunken ship, No. 7 HaeSung. It calculates the member value required for the structural stability assessment, and estimates the central transverse section, and the corrosive rate. In chapter 4, we analyze the ultimate strength and also perform the structural stability assessment by the program of the hull structure.

3. The Structural Stability Assessment of the Sunken Ship, No. 7 HaeSung

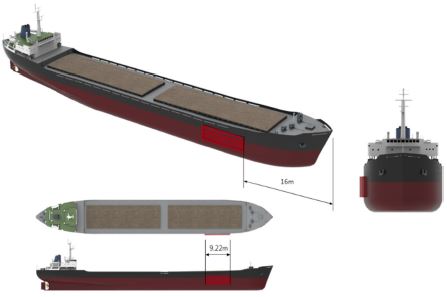

No. 7 HaeSung was manufactured in 'SHIKOKU DOCKYARD', Japan, in 1962, and was given the current name in 1989. While in operation, the ship sank 1.5 miles southwest off the coast of Sindo-ri, Haui-myeon, Sinan-gun, Jeollanam-do on 6th of July, 1990. Table 1 shows the critical information of the ship’s design. In order to accurately assess the structural stability of the sunken ship No. 7 HaeSung, we required the structural drawings of the ship. However, it was nearly impossible to acquire the drawings and related materials due to the withdrawal of classification from Register after the accident. Therefore, this study was performed with reference to the base drawing of similar ships, in order to draw the shape and the hull structure of the target ship.

3.1 Extent of hull damage and estimation of the condition

Damage can be estimated through the materials, the written observations, the image data, or related regulations regarding the ship at the time of the accident. Any information about the site and size of the damage can be used to estimate the position and size of the damage recorded in the data. However, when information about the damage size is missing, then as per regulations, the smallest damage has to be assumed. The designated standard of the damage size to the ship is presented in MARPOL/IBC Code, in which the ship can stand against the damage considering the range of flooding (IMO[2007]). No. 7 HaeSung sank due to a marine accident, but there was no information in the written findings or related materials, except the position of the damage. Moreover, the initial damage at the time of the accident could not be estimated by multi-beam echo sounder 3D image investigation, due to the failure of the hull structure. The cargo hold of No. 7 HaeSung was damaged during a collision on route No. 1. The angle of the collision was 75 degrees from the freeboard of the opposite line. After the collision, the hull first collapsed from the freeboard, and sank within 2 minutes of the impact. Table 2 shows the estimated size of the damage to No. 7 HaeSung, based on the regulation of the damage size.

In case of, it can be considered that No.7 HaeSung has sunk because the damage was more than the range values of Table 2. Table 2 shows basic information on sunken ships, and Fig. 2 shows the estimated damage of the hull structure at the time of the accident.

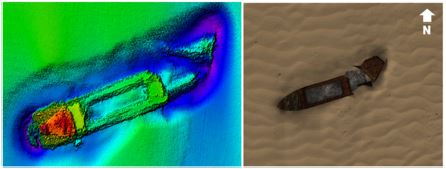

Position of the Sunken Ship: In order to recover the shape, the surrounding topographic map was drawn by using 3 D phase information of the multi-beam echo sounder obtained in the on-site scan. The implementation method had to output the color spectrum expressing the depth of the seabed from 3D image data, and to remove the vessel shape and noise through image editing using Photoshop and other programs. After converting the color spectrum into black and white by using the technique of 'Height Field from Image', 3D configuration of the sea bottom was realized. The status of the vessel was estimated through 3D image data obtained by the on-site investigation, which reflected the sinking position and the damage information. Figure 3 shows the image data of No. 7 HaeSung, and the estimated sinking position was drawn from the on-site investigation.

As seen in Figure 3, No. 7 HaeSung had the freeboard that was bottomed with the condition toward the northeast and had a collapsed hull. In the vertical position, the freeboard turned upward towards the bow at a degree of 2~6, and was about 0~2 degrees in the horizontal slope. The front body of the cargo hold, No. 1 was inclined to the north at the degree of 20, due to the structural failure.

3.2. Drawing the Cross Section of the Sunken Ship

The mid-ship section coefficient in the stationary state of the vessel is presumed in order to evaluate the structural stability, assuming that the ship was built and operated in a normal way. In order that the hull structure is able to withstand the applied load of the ship, the longitudinal bending moment, shearing and the bucking strength are defined by the classification of each country from around the world. The sunken ship may have been built by the corresponding standard; the main particulars of the ship (the vessel class, the length, the width, the depth, the displacement, etc.) may have held the appropriate mid-ship cross section modulus.

According to this assumption, the mid-ship section modulus in the stationary state of the vessel is estimated, following which the strength of the longitudinal structural members is measured by the modulus. The standard for the assessment of the longitudinal strength is the mid-ship cross section modulus Z, which is calculated by the calculus as suggested by Register. The calculus of the section modulus is presented in Table 3, as suggested by Korea Register of Shipping.

The section modulus is divided into the minimum section modulus (Zmin) and section modulus (Z1); the minimum section modulus of the target vessel is calculated according to the regulations defined by the core resources of the ship at that time. The section modulus of Z1 is the value is calculated under conditions designated for loading, and has to be more than the value as suggested by the Register. In order to calculate the section modulus of Z1, the moment value of bending of ships inflicted by the waves is needed, with the moment of bending of ships in the stationary state. Though this can be estimated as suggested by Register, it cannot be presumed in the current state as the moment of bending of ship can be produced after the calculation of fundamental performance.

Therefore, in order to estimate the appropriate level of the section coefficient value, this research compares the values of the section modulus and the minimum section modulus with ships of a similar size, confirms that the value of the section modulus is in the range 110-120% of the smallest section modulus, and presumes that the value of the section modulus for the sunken ship is 115% value of the smallest section modulus. If there is no information about the sunken ship, the core resources and the information needed to calculate, is consulted by the data of similar ships.

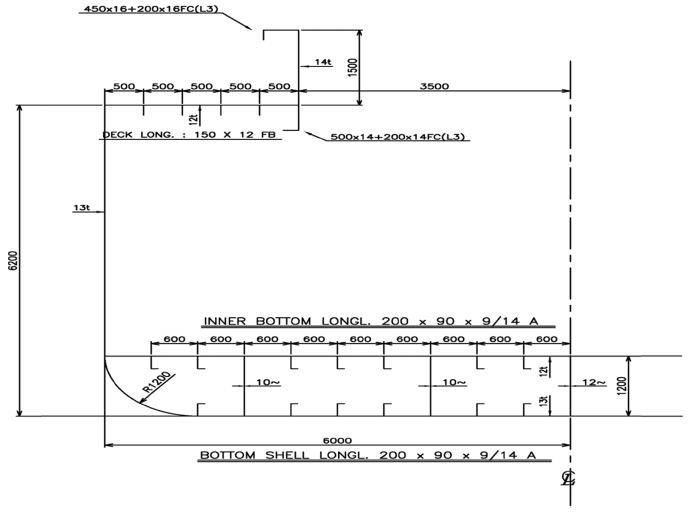

With respect to the basic specifications of No. 7 HaeSung, the length (L), width (B) and depth (ds) are 84 m, 12 m, and 6.2 m respectively, and the value of the section modulus Z1 is 1,025,140 cm2.

In the designing process of the hull structure, the rule scantling of the sunken ship can be defined as the work calculating the member value which has ‘the required strength’ in order to withstand a given designated load. The details, which performs the calculation about the strength based on the regulations for the specification selected by the ship owner, have to include investigating the rule scantling and the longitudinal strength in general. However, as there is no information about the size and the external forces that act on the structural sub-materials, this research investigates the longitudinal strength. The method of calculation of the rule scantling is to temporarily draw the central cross section of the target ship, and to calculate the transverse section coefficient with reference to this. It compares the value of this calculation with the section modulus of the vessel in need, which is estimated in section 3.2.1. If the section modulus is smaller than the section modulus in need, it means that the ship does not have the necessary longitudinal strength, and this can cause a structural problem; thus, the position of the sub-materials in the central section design, the scantling size, etc. need to be revised. This task has to be repeatedly executed until the section modulus of the mid-ship section design satisfies the necessary value of the section modulus.

The drawing of the mid-ship cross section shows the size of the hull structure members, the layout of the hull structure, the method for mutual adhering of structure members, etc. The mid-ship section structure occupies more than 60% of the length of the vessel. It further needs to be evaluated after drawing, so that the structural shape of the mid-ship determines the total weight of the vessel and the longitudinal strength. The arrangement of the transverse structure members is determined according to the length and width of the vessel. In this sunken ship, it is determined with reference to the arrangement of the transverse structure members in a similar ship and as per the regulations of the Register. The dimension of the kind girder is referred and chosen by the dimensions of a similar ship. As presented in Figure 4, the general drawing of the mid-ship section of No. 7 HaeSung is shown.

3.3 Estimated rate of hull corrosion

As the age of vessel increases, so does the damage to the structural strength, since corrosion and fatigue proceed rapidly. Corrosion in seawater is more acute than that in fresh water. This is mainly due to the 3.5% sodium chloride (NaCl) present in the seawater. The sodium chloride (NaCl) is more concentrated where the metal shows the strongest corrosion tendency (Baek[2004]). The corrosion does not happen while the anticorrosive coating preserves the stationary state. After the coating is damaged, the transition during the specified period passes by, and the corrosion progresses according to the nature of the submaterials. The lifetime of the coating depends on the kind of coating used, and how it is maintained. In general, it is considered to be about 5~10 years lifetime in case of a ship.

This research considered two ways to estimate the degree of corrosion of the sunken ship. The first method was to assume the worst situation, the condition of the corrosion, and to estimate the maximum value of the degree of corrosion. In this scenario, it assumed that the anti-corrosion coating was not administered at all and the corrosion started immediately after sinking, without a transition period. Moreover, the corrosion rate of the hull used the largest scale of corrosion rate under the water among the materials of the corrosion rate for each structural sub-material, as suggested in the Register. The rate of corrosive progress before sinking was estimated at 0.127 mm/Year of coating lifetime 5 years, and the calculation of the corrosive progress rate after sinking was estimated at 0.163 mm/Year of the coating lifetime 7.5 years, as the speed of the corrosion was assumed to progress and accelerate rapidly due to the damage of the outer ply in the event of submersion.

The second method estimated the smallest value of the corrosion rate before sinking, as evaluated by a routine check-up for the vessel, for which the coating was maintained and mended normally. In this case, the coating lifetime was maintained for 5 years after sinking. It was assumed that there was minimal degree of corrosion before sinking, in which there was no corrosion. The corrosion rate after sinking was estimated at 0.115 mm/Year, which was the result of the on-site investigation. This was because the deviation of the corrosion rate was higher according to the position of the sub-materials, and the smallest value cannot represent the degree of the corrosion of the sunken ship.

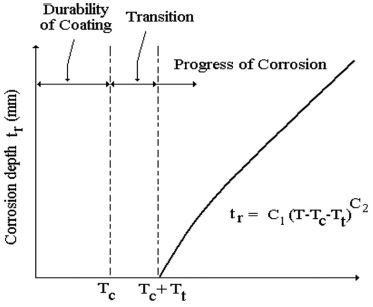

Figure 5 shows the progress of the general corrosion.

The organization of the equation that showed the estimated progress of the hull corrosion was classified as the coating lifetime, the transition period, and the progress of the corrosion. Here, C1 defined the annual rate of the corrosion progress, T the age of the vessel, Tc the coating lifetime, Tt the transition period after the coating lifetime, and C2 the tendency to the corrosion (0.3-1.0, Default: 1.0) per each.

The degree of the hull corrosion of No. 7 HaeSung was estimated based on an estimating method as described in section 3.3.1, and is presented in Table 4. According to the table, the thickness was originally 13 mm, 12 mm in the case of the outer ply and inner bottom plating, which was meant that the former retained a thickness of 8.28 mm, and the latter retained a thickness of 7.28 mm in 2016.

4. Assessment of the Structural Stability of the Target Sunken Ship

4.1 Analysis of ultimate strength of hull structure of the sunken ship

Analysis of the ultimate strength of the hull structure is the work that evaluates the structural stability from the result generated through the calculation of the structured response about the load acting on the vessel, and from the criteria of intensity and the structure of materials. A longitudinal strength assessment, shear strength calculation, local strength estimation and structural analysis are usually carried out to evaluate the vessel’s structural stability. To this end, it is a prerequisite to calculate the external force working against the hull.

- force bending the hull in a longitudinal direction (longitudinal bending moment)

- distorting the horizontal plane of a ship (horizontal load)

- force twisting the hull (twisting moment)

- forces working locally (various kinds of local loads)

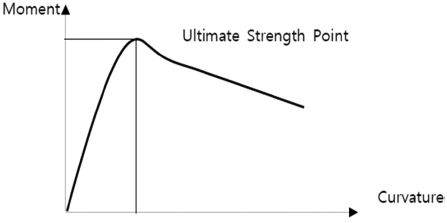

In case of the sunken ship, the hydrostatic pressure does not operate either within or outside the hull, and there is no load from the tidal waves because the ship is mostly flooded by the seabed; it is quite different from normally operating ships. The loading that acts on the sunken ship can be estimated by the impact at the time of bottoming onto the seabed, the heavy body, along with the load due to the remaining goods of the cargo hold, the constant state in contact with seabed, the flow of tidal waves, and the combined load of these loads. This load may be considerably smaller than the load of normally sailing ships. However, if the corrosion proceeds drastically, structural destruction can happen even with a small load, and it is very likely that the remaining fuel oil and the remaining goods of the hull could be discharged. In the case of a sunken ship, it is almost impossible to accurately estimate the type and intensity of an external force acting on actual structural members. Therefore, this study performed a limited longitudinal analysis on the collapsibility of the hull structure. As a usual, the hull structure design is developed based on a single representative transverse section, or a central cross section, and the dimensions of the members are 40 to 60% of the length of the central part of the entire hull. As a result, the maximum value of the longitudinal bending moment acting on the hull occurs in the central part of the entire hull. The drawing of the mid-ship section is the result of the empirical formula and data of a similar ship, when there is no exact information about the actual ship, making it difficult to know the accurate applied load of the relevant ships’ design or the criteria of structural damage. Therefore, it is impossible to suggest the exact time about the potential failure of the sunken ship. In addition, the analysis of ultimate strength performs for the purpose that estimates the time when the structural failure rises roughly through the analysis of ultimate strength taking the hull damage size and the corrosive rate of the structural members into consideration, and is utilized for the risk assessment of the sunken ship. The principle of the ultimate strength assessment is to use the correlation between the bending moment and curvature. If the overall curvature increases even though the increase in curvature in proportion to a surge in bending moment stops at a certain point, it can be defined as the ultimate longitudinal strength. The members engaged in the longitudinal strength of the ship reach the yield stress or elasto-plastic buckling occurs if the hull structure is placed under a load condition closer to the ultimate longitudinal strength, causing a gradual collapse. Fig. 6 shows the correlation between the increase in bending moment and the curvatures.

The assessment for the analysis of ultimate strength is evaluated as the ratio (ηM) of the ultimate strength (Mult) that acts on the bending of ships. For the simplification of the evaluation method, this analysis is performed under the condition that the ratio of the initial ηM: Mult/Mact of the sunken ships is assumed as 1.2. This is by taking the architectural design safety rate into consideration at that time.

4.2 Assessment of the structural stability

The structural stability of the damaged hull is considered dangerous when the ratio (ηM: Mult/Mact) of the moment (Mact) that acts on the vessel and the ultimate strength (Mult) that holds the hull is less than 1 (ηM <1) (Kim et al.[2014]). Since this standard is mainly for ships under normal operation, it cannot be applied directly to a sunken ship. By taking into consideration small loads acting on the hull of a sunken ship and the corrosion conditions, the value of ηM is estimated at approximately 0.5 for the criteria to assess the current structural stability, but this value needs further systemic research.

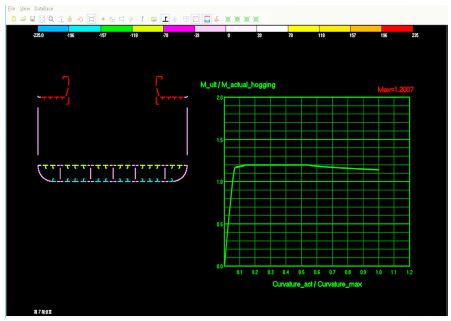

Figure 7 is the screen that revaluates the ultimate strength after applying the degree of corrosion to the hull structure. The value of ηM is assumed as 0.63 in the current status, in which there appears to be a low possibility of the failure in the hull structure. However, there seems to be a high possibility that the hull structure will collapse because of the growth for the degree of corrosion over the time afterward.

5. Conclusion

This study proposed the method and procedure to assess the structural stability of a sunken ship, in order to evaluate the possible discharge of harmful materials, by considering the age of the sunken vessel and the corrosion rate and damage size.

Safety assessment on sunken ships has not been studied yet, and it is very difficult to get design drawing which might provide structural information of sunken ship. On this study, we used basic information only and could generate configuration of the sunken ship and calculate its structural dimension. And by referencing of sinking field 3D image, we estimated sinking condition at sea floor and damage state of the ship structure.

Moreover, it estimated the potential failure of the hull structure considering that the corrosion of the hull structure and the damaged structural members may have an influence on the structural stability of the ship after sinking. In case of the target sunken ship, the bow structure was destroyed and detached from the hull structure after sinking, for reasons unknown. This destruction of the bow structure may have an effect on the longitudinal strength of the vessel, and the total structural stability. This in turn requires additional research. Though there was a low possibility that the potential failure of the whole hull structure happened in the current status, the possibility that the hull would collapse because of the growth for the degree of corrosion over the time afterward.

The evaluation method for assessment of structural safety of a sunken ship as suggested by this study, will contribute to analyze and interpret the collapsibility of the sunken ship due to the corrosion, earthquake, and tidal waves, etc., and the potential failure of the hull structure will be considered along with the possible toxic discharge, among the evaluation factors for the degree of harmfulness of the sunken ship.

Acknowledgments

This study is a part of the research results of “The initial response to the marine accident and the development for the rescue technique support system” conducted by KRISO (Korea Research Institute of Ships and Ocean Engineering).

References

- Baek, K.K., (2004), “Corrosion and Protection of Ship’s Hull and Marine Structure”, J. Corros. Sci. Soc. of Kor, 3(1), p28-42.

- IMO, (2007), “IBC (International Bulk Chemical) Code.”.

- Kim, W.D., Kim, S.T., Kang, T.W., Jang, M.J., and Choi, J., (2014), “Development of Damage Safety Assessment System for Special Ship”, Annual Spring Conference on the Society of Naval Architects of Korea, Busan, Korea, 22-23 May 2014.

- Korea Institute of Machinery & Materials (KIMM), (2009), “Ultimate Strength of Damaged Ship Assessment System User Guide.”.

- Korea Marine Environment Management Corporation, (2014), “Sunken Ship Management Business.”.

- Korea Register of Shipping (KR), (2015), “Rules for the Classification of Steel Ships-Part 3 Hull Structures.”.

-

Lee, S.H, Choi, H.J., and Suh, J.J., (2015), “A Study on the Improvement of Risk Assessment Items and Index for Sunken Ship,”, J. Korean Soc.Mar. Environ. & Safety, 21(6), p704-711.

[https://doi.org/10.7837/kosomes.2015.21.6.704]

- Ministry of Oceans and Fisheries, (2015), “Sinking Ship Management System.”.